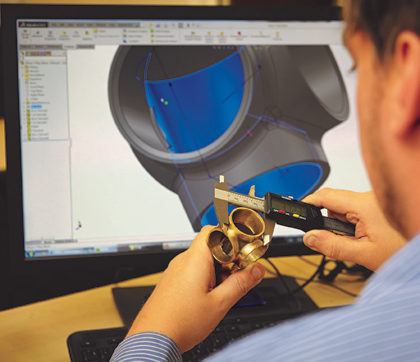

The British luxury towel warmer, washstand and accessory manufacturer, The Sterlingham Co Ltd, last month acquired SolidWorks to allow its design team to offer 3D models of all of its products. This move has already demonstrated a more effective design process, a dramatic reduction in time to market, and has enhanced the already high-standard of customer product, support and service. ????

With plans for a new range of accessories in 2015 and the high demand for bespoke work, the decision to move to 3D CAD (Computer Aided Design) modelling was in many cases a natural step and a true investment in the design culture at The Sterlingham Co Ltd. ????

Andrew Healey, General Manager, The Sterlingham Co Ltd, commented: ?When I joined the Sterlingham Co Ltd in November 2013 I began looking into CAD systems as the next natural progression for the design team. The team from CADTEK (SolidWorks Reseller) visited us in August and gave a presentation of the software showing its capabilities and the decision was made in seconds.??

?????The Sterlingham team were able to pick up and start creating models within the first 2 days of having the software and benefitted massively with the on-site training we provided.?? Jamie Thain, CADTEK design engineer added.????

The 3D models can be shared in many formats, the most appealing being through eDrawings software which allows the company to send drawings that can either be electronically stamped for approval or have modification requests noted. ????

Andrew Healey concluded: ?We have already, in such a small space of time, seen the clarity and speed of instruction with our customers improve in both directions. The eDrawings app is particularly great for our customers as it allows them to print off a QR barcode, which when viewed through the screen of an iPhone or iPad, shows the product in what is called ??augmented reality??, it allows you to see the product in the environment it is intended for and even in the place it is intended for. The technology is very impressive and our customers truly appreciate being able to see products in situ.?? ????

Case Study

????Recently a European retailer approached The Sterlingham with a request for a bespoke shower screen grab rail, a basic concept of the design was given based on one of the company??s existing products. Within a day, a 3D model was drawn up showing the grab rail design and the added components which would allow the securing of the rail to a glass door. This was sent back by the customer with a few slight modifications. Within the space of a 2-3 day period the final design had been signed off. Three weeks later the new grab rail was received by the customer and orders have since been placed. ????

Future Plans????

With the release of a new towel warmer brochure in the coming weeks The Sterlingham team has now generated 3D models of all the products being sold as standard. These standard towel warmer models can be modified with ease upon taking any bespoke size requests. ????

Following release of the towel warmer brochure the company is aiming to release a new accessory range in 2015 to complement its current Classic and Craftmaster ranges. ????

Kelvin Pearce, Managing Director, The Sterlingham Co Ltd, commented: ?Whilst I believe many people in the market place relate to The Sterlingham products as being extremely high quality, beautifully crafted and designed, the focus is to ensure our customer service and support matches. It is with this in mind that we look forward to releasing our new brochures and offering both new and existing customers the benefits of our company??s vast knowledge and experience through service extras such as the 3D CAD models.??

01384 370901 | www.sterlingham.co.uk