With the Cofraplus 220 floor system, Arval, the brand from ArcelorMittal for innovative sheet-steel construction elements, is introducing a lightweight, cost-effective solution for building long-span flooring structures.

Sophisticated sectional geometry for high performance in a number of applications??

Easy, friendly floor system permitting the design of continuous slabs for cost-effective load bearing characteristics??

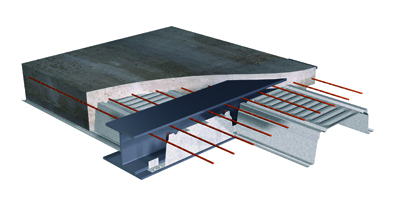

The floor system is measured taking into account its additive effect. Here, the concrete cross section of the ribbed floor and the sheet metal are each involved in the load transfer separately, not taking into account any composite action. The total load-bearing capacity of the floor is thus produced through simple addition of the two load bearing portions. In addition to the considerable moment of inertia of the 220-mm floor slab, particularly favourable in critical designs, the Cofraplus 220 System permits a static continuous-slab design above the beams as intermediary supports. The sheet metal sections are supported via so-called wings. These are 3-mm-thick sheet metal parts fitted to the profile shape, which are factory-welded directly to the web of the composite steel beams. The attachment of the wings to the web can vary based on the specific project. If required, the crown of the sheet metal section can be positioned over the upper edge of the support flange. In this way, the composite steel beam as the main weight-bearing element can be optimized in a more independent manner without increasing the thickness of the concrete floor between beams and thus also increasing the intrinsic loads. Because they are supported by the wings, the sheet metal sections are brought right up to the web, along with the ribs of the floor system which will be concreted at a later time. This construction achieves a high transverse load bearing capacity between the support and sheet metal, providing the prerequisite for redistribution of moments of inertia and enabling a more cost-effective measurement on the basis of a continuous slab design.

Spans of up to 6.3 m without propping ?? even while construction is in progress??

The loads generated in the construction phase are generally a crucial factor in designing long-span floor slabs, since the fresh concrete has not yet solidified, and the slab is the only element ensuring load transfer. Thus it is the condition of the concrete that represents a critical load for the sheet metal section, even if a more favourable safety coefficient in the design concept can be selected here. Depending on the intrinsic weight of the concrete and the thickness of the floor above the sheet metal, the Cofraplus 220 System permits spans of up to 6.3 m without propping in the construction phase. If temporary joists are used during the construction phase, a support-free span of up to 10.0 m is even possible in the final construction. In such cases, the ribs must be held by appropriate supports in order to avoid a local stability failure.

Prefabrication and assembly with minimal tool requirements

In conjunction with an integrated Slim floor beam from ArcelorMittal (CoSFB ?? Composite SLIM FLOOR BEAM), the system can achieve support-free grid dimensions of approximately 10 m x 10 m. This underscores the performance of the Cofraplus 220 floor system as a lightweight, cost-effective solution for long-span floor structures in multi-storey buildings, and particularly in car parks.