Rapid growth at Norwich-based glazing manufacturer, Norwich Aluminium Limited, has seen the company move to new 80% larger premises and employ five new staff as it continues to fly the flag for UK manufacturing in construction.

Norwich Aluminium was established six years ago by local man Alex Warren. Alex, who was working in the glazing industry at the time, spotted an opportunity to move into aluminium, a material which was growing in popularity for commercial and architectural glazing. By re-mortgaging his house, Alex set up the company in a unit on White Lodge Trading Estate in Norwich, next to other established brands such as Screwfix and SIG.

Alex explained: “Using my knowledge of the PVC-U market, I could see the growing opportunity in aluminium. I knew that if I wanted to take the leap, I had to react quickly to market trends and invest properly. The banks were not interested at the time, so I raised the funds myself to get going and set up a small manufacturing facility in Norwich. We started with just three staff.”

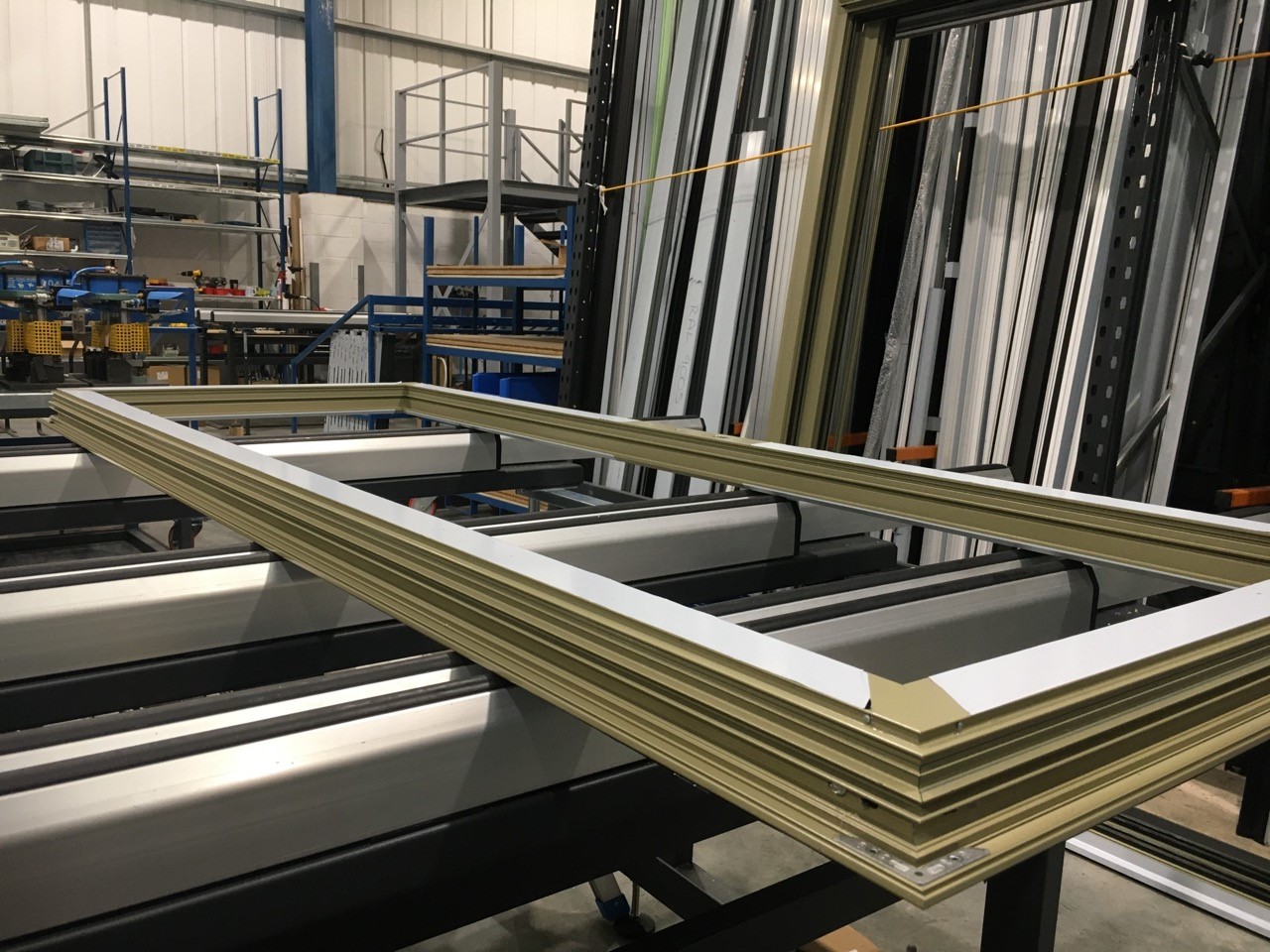

Norwich Aluminium manufactures glazing for domestic and commercial projects. It recently completed glazing for new wards at the Norfolk & Norwich Hospital, some of which are currently being used as emergency COVID-19 wards. The company has worked on hundreds of projects across the country, ranging from new and existing schools and shop fronts to home renovations and commercial offices. Norwich Aluminium is very proud of the foothold gained in the local Norwich area and neighbouring counties, working on some high profile and stand-out architectural buildings. Recent projects have seen the company diversify and move further afield, reaching from Brighton to Edinburgh, to work with retained clients.

In December 2020, they set up subsidiary company Norwich Aluminium Trade Supply, with a focus on manufacturing a quality aluminium product for other glazing companies that are involved in installation-only projects and looking for a reliable local supplier.

Today, Norwich Aluminium employs 30 full-time staff across the group. Having outgrown its premises, Alex has invested £340,000 to move to new 80% larger offices and a bespoke manufacturing facility on the same industrial estate. The offices have been designed, manufactured and installed by spatial designers and event agency Production Bureau and comprise workspace and meeting rooms, as well as a staff canteen. The manufacturing premises include new top-of-the-range equipment and work benches to allow an increase in production, as well as a better space for the staff, who have been key to the success of the business.

Alex Warren continued: “In 2020 alone we manufactured over £3 million of aluminium glazing products for customers across the country. We are targeting a 30% growth on that figure this year. While the UK construction and manufacturing industries continue to struggle, our future order book is looking very strong. We’re bucking the trend and still growing. We pride ourselves on quality and moving to these new premises will enable us to offer an even better service for our customers using the latest manufacturing facilities. We are looking forward to seeing what the future brings.”

For more information on Norwich Aluminium, visit www.norwichaluminium.co.uk and www.norwichtradesupply.co.uk